As global industries push towards sustainability, efficiency, and lower emissions, so does the truck loader crane market. Manufacturers like HMF are reimagining how this essential machinery can operate more responsibly. And we’re excited, because loader cranes, once just viewed as the workhorses of logistics and infrastructure, are now at the forefront of this transformation, which is our forte.

Across the market, supply chain trends are focusing on electrification, smarter hydraulic systems, energy-efficient components, and the use of reduced heavy materials.

It’s reshaping how crane operators get work done and is impacting market growth. With detailed insights, HMF continues to lead the charge toward a more sustainable, high-performance future for loader cranes. We’re helping construction companies (and other business owners) build a more efficient, reliable, and future-ready fleet in the truck loader crane market.

Sustainability in Loader Cranes: Reducing Carbon Footprints

To understand the new market dynamics, we first need to look at the old. Traditional loader cranes have long relied on hydraulic systems. Anyone who’s worked with these will know that while they’re powerful and reliable, they also burn through significant amounts of fuel. And with engines idling for extended periods, there’s even more unnecessary emissions and wasted energy.

However, today, sustainability (like in many things) is a major force in rethinking how loader cranes are built and operated. Our manufacturing peers in the global market, including the Middle East and South Korea, are embracing lighter, stronger materials that reduce overall vehicle weight. As a result, a lighter crane means lower fuel consumption, fewer emissions, and a healthier bottom line.

Furthermore, these technological advancements are also cutting environmental impact at the source with precision engineering, material optimisation and advanced coatings. These emerging trends all help extend component life while reducing waste and energy use in production.

Finally, on the operational side, innovations like reduced idling, intelligent power management, and energy recovery systems are transforming how efficiently cranes use energy.

Those in the construction industry should be excited about these changes. You can lower fuel costs, extend equipment life, and significantly shrink your carbon footprint. And in case you’re wondering, you’ll still maintain the same strength and performance as traditional crane equipment.

Electrification and Hybrid Systems: The Next Generation of Power

It’s not just Teslas and Toyotas making waves in the electric and hybrid space. The movement toward cleaner, more efficient power is significantly impacting the heavy equipment industry, too. And crane trucks are benefiting from this transition, with electric and hybrid truck chassis creating new opportunities for quieter, lower-emission operations.

Here’s the important distinction: vehicle loading cranes themselves remain hydraulic systems—that hasn’t changed. What’s evolving is the integration between modern electric or hybrid trucks and the hydraulic cranes mounted on them. HMF is actively working with truck manufacturers to ensure their cranes can be powered effectively by these alternative-fuel vehicles, using technologies like variable flow valves to optimise the hydraulic system’s connection to the truck’s power source.

Benefits of Electric and Hybrid Truck Integration

When loader cranes are mounted on electric or hybrid trucks, the complete crane truck unit delivers several advantages:

Reduced Operating Costs: Electric and hybrid trucks offer lower energy costs and less frequent maintenance compared to traditional diesel trucks, reducing the overall running costs of the crane truck.

Quieter Urban Operations: The truck’s electric motor significantly reduces noise during transit and positioning. This means less disruption when working in residential areas or noise-sensitive sites—particularly valuable for early morning or late evening work.

Lower Emissions: Electric and hybrid trucks produce fewer emissions during operation, helping construction and logistics companies meet increasingly strict environmental regulations and sustainability targets.

Maintained Crane Performance: Because the crane itself remains a proven hydraulic system, lifting capacity, reach, and reliability stay consistent regardless of whether it’s mounted on a diesel, hybrid, or electric truck.

The Practical Reality

While the crane’s hydraulic systems continue to deliver the same robust performance operators rely on, the shift to electric and hybrid trucks is creating cleaner, quieter crane trucks for urban construction sites, logistics operations, and noise-sensitive applications across Europe and increasingly in Australia.

The technology isn’t about reinventing the loader crane—it’s about adapting proven crane technology to work seamlessly with the next generation of truck chassis.

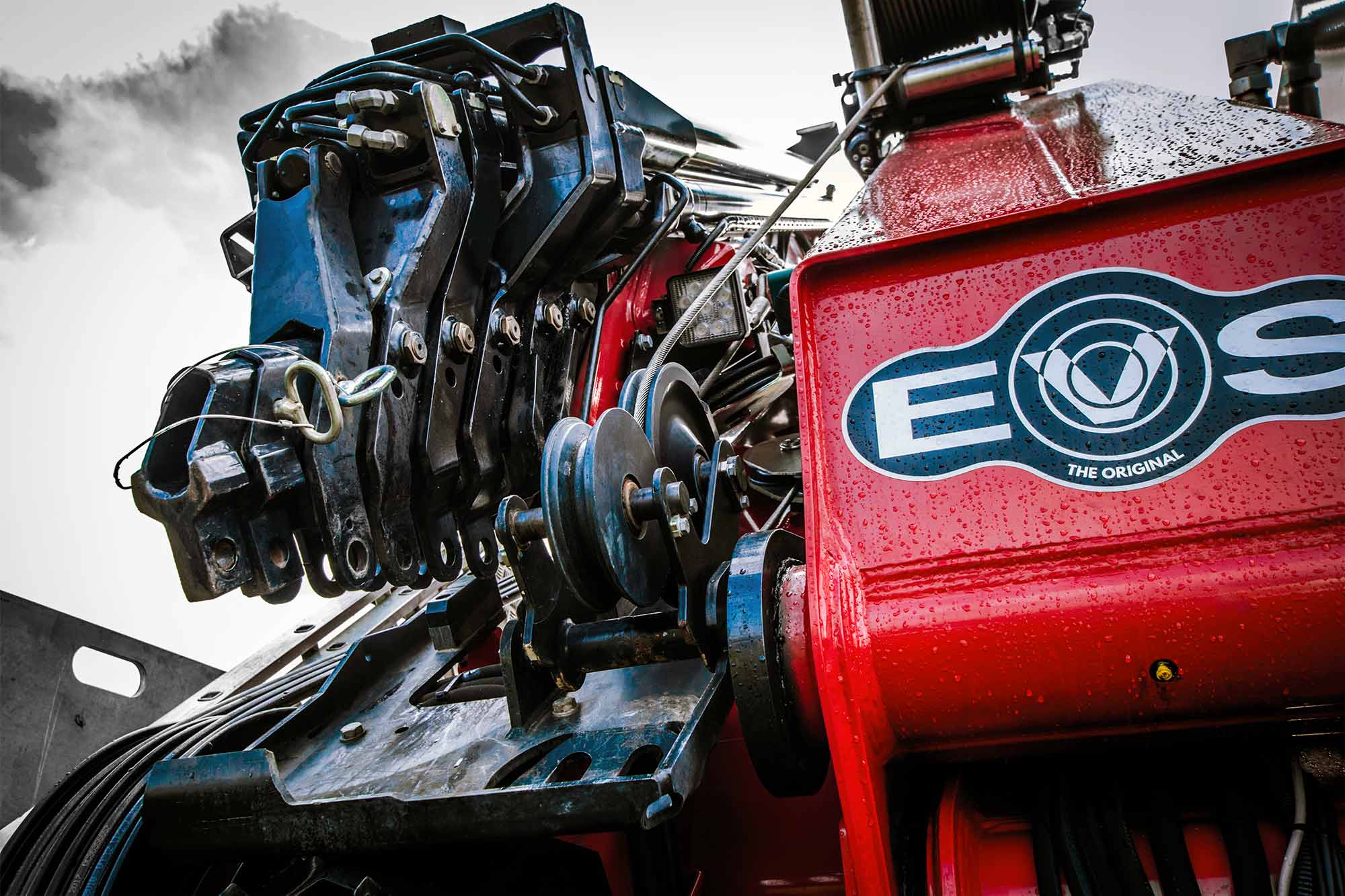

EVS System

HMF has been an industry leader in this area, with arguably our most recognised innovation being the EVS (Electronic Vehicle Stability) system. This advanced safety feature ensures safe and efficient crane operation through intelligent load and stability monitoring. When combined with modern energy-efficient technologies, it helps operators maintain safety while optimising performance.

Efficiency and Smart Control Systems

Beyond electrification, there’s innovation in intelligent systems that significantly enhance safety, efficiency, and operational reliability.

Load management and automation

Modern loader cranes powered by load-sensing pumps are now equipped with advanced load management and automation technologies that continuously monitor weight distribution, boom angle and lifting conditions.

As a result, they automatically optimise power output, ensuring every movement is precise and energy-efficient. The benefits of this are reduced fuel use and mechanical wear over time.

Digital Diagnostics

Digital diagnostics have also transformed maintenance. Instead of relying on scheduled servicing alone, cranes can now self-detect performance anomalies. The tech alerts operators or fleet managers before issues become breakdowns, which, as you know, can be extremely costly. This predictive approach extends equipment life and minimises downtime.

Telematics and Real-time Monitoring

These tools give fleet managers a live overview of crane utilisation, energy consumption, and performance metrics across multiple job sites (remotely), resulting in data-driven decision-making. You can schedule maintenance to improve operator efficiency. Benefits include better productivity and sustainability goals.

In short, by improving precision, automation, and data visibility, you can do more with less.

Economic and Operational Benefits for Businesses

Investing in modern, energy-efficient loader cranes doesn’t just tick sustainability boxes; it delivers financial and operational cost benefits.

Several factors achieve this by:

- Reducing fuel consumption

- Minimising wear through intelligent load management

- Cutting maintenance needs (especially truck chassis)

- Increased uptime (fewer operational delays)

- Lowering risk of costly incidents

- Reliable vertical transportation

We’re already seeing businesses getting a return on investment in Australia’s emerging markets, as well as the rest of Asia Pacific. In short, these cranes aren’t just better for the environment and logistics operations; they’re better for your bottom line.

Looking Ahead: What’s Next for the Loader Crane Industry

We’re in exciting times as technology continues to evolve with innovations that will further redefine the loader crane industry. We’re witnessing AI change the world, and this includes the loader crane industry. Along with IoT integration, these innovations enable predictive maintenance, allowing operators and fleet managers to anticipate issues before they arise.

Furthermore, we’re noticing that Government policies and incentives are also influencing adoption rates. They encourage businesses to invest in low-emission, energy-efficient crane trucks to meet ESG targets and regulatory standards.

For fleet managers and construction companies, the key takeaway is clear: partnering with future-ready crane suppliers like HMF ensures your investment stays relevant, adaptable, and compliant as the industry continues to move toward sustainability and working smarter, not harder

Building a Smarter, Cleaner Future

As you can see, electrification, hybrid systems, and smarter crane technological innovations are rapidly transforming the loader crane industry and sales aftermarket, delivering efficiency, safety and sustainability.

By embracing these modern cranes, you can reduce costs, lower emissions, and future-proof your operations. Explore how at HMF, where our loader crane solutions help your fleet stay ahead of the curve and future-proof your business in the competitive landscape.