We’ve seen it time and time again—businesses invest in a crane without fully understanding what they’re getting into, only to learn the hard way about what they should have known. Buying a crane isn’t just another equipment purchase; it’s a major and sometimes single most important investment in your business.

As such, we want to cover what every first-time crane buyer in Australia needs to know. We’ll draw on real-world mistakes we’ve seen firsthand, whether it’s choosing the wrong crane type, underestimating ownership costs, or overlooking licensing and maintenance. This way, you can avoid the same pitfalls and make a smarter investment.

Why Consider Buying a Crane?

The big question is: should you buy or hire? For many first-time buyers, we generally recommend hiring before you buy. That said, if you’re going to be regularly using cranes for your business operations, ownership may offer better value in the long run.

Crane ownership makes the most sense when:

- You’re working on long-term projects that require regular or daily lifting tasks

- You frequently need a crane on hand to avoid hire delays or scheduling conflicts

- You need a specific crane configuration tailored to your typical work

- You want to reduce long-term hire costs and invest in equipment equity

- You’re expanding your fleet and need dedicated lifting capacity for multiple job sites

For example, a civil contractor handling multi-stage infrastructure projects may find hiring impractical or too expensive over time. Similarly, a construction company with multiple crews working across regions can benefit from owning a crane that’s ready when and where it’s needed.

What Type of Crane Do You Need?

So, you’ve decided to buy a crane, and now, the logical next step is choosing the right type for your work. Cranes aren’t one-size-fits-all, so you will want to have a firm grasp on the type of projects you will be using your crane for.

Here are four key questions to ask yourself:

- What is the project scale?

- What type of lifting will you be doing?

- What is the terrain you will be working on?

- What is the frequency of use?

Now, once you have answered the above, take a look at the most common crane types and when they’re typically used:

- Mobile Cranes – Versatile and easy to move between sites. Therefore, ideal for general lifting tasks in construction and logistics. Great for short-term, varied projects.

- Crawler Cranes – Track-mounted and built for heavy lifting on uneven or soft terrain. Best for large-scale infrastructure, civil works, or long-term sites with limited mobility needs.

- Tower Cranes – Fixed overhead cranes used primarily for high-rise construction. They offer impressive height and reach, but are a long-term, site-specific investment.

- Truck-Mounted Cranes – Cranes mounted directly onto road-registered trucks, offering a combination of mobility and lifting power. Perfect for contractors who need flexibility across multiple sites.

For example, a construction company working across urban sites may benefit most from a truck-mounted knuckle boom crane. They are easy to transport, quick to set up, and compliant with road regulations.

Understanding Crane Ownership Costs

Much like buying a car, it isn’t just about the driveaway price. We see many new buyers fail to consider the full operating costs over time, and they often underestimate the ongoing expenses that come with keeping it running like a well-oiled machine. Here’s a breakdown of what to expect.

Upfront Purchase Price

Obviously, this varies depending on the type of crane you purchase. A new crane can range from $100,000 to over $500,000. Customisation, load capacity, crane model, and features like remote control, hydraulic extensions, mobile crane types or safety features will also impact the final cost.

Maintenance and Inspections

Cranes require regular servicing, including hydraulic checks and wear-part replacement. Additionally, cranes must remain compliant with AS 2550 and AS 1418. As a result, you need to budget for scheduled maintenance, emergency repairs, and genuine replacement parts.

Insurance

Expect to insure both the crane itself and its operational use. This typically includes:

- Equipment damage

- Public liability

- Operator coverage

Each has premiums varying based on crane type, age, and application.

Transport and Setup

If you’re not using a truck-mounted crane, you’ll need to factor in:

- Transport logistics,

- Pilot vehicles

- Permits and setup costs (particularly for larger crawler or tower cranes

Operator and Compliance Costs

Hiring or employing a licensed operator is not a choice but a must. Unqualified use not only voids insurance but can attract serious fines, not to mention being unsafe. Some projects may also require spotters, riggers, or additional documentation.

Licensing & Legal Requirements in Australia

In Australia, you can’t legally operate one without the proper licences and compliance paperwork in place.

Here’s what you need to know:

- Licences: Most cranes require a High Risk Work Licence (HRWL), issued through each state or territory’s workplace safety authority. Different crane types—such as vehicle loading cranes, slewing cranes, or tower cranes—require different licence classes (e.g. CV, CN, C2, C6, etc.).

- Business Owner vs Operator: Even if you’re not the one operating the crane, as the business owner or site manager, you’re still responsible for ensuring your operator holds a valid licence and that the crane is compliant and safe to use. That includes regular servicing, inspections, and maintaining up-to-date records.

- Regulations and Standards: Cranes must comply with Australian Standards like AS 1418 (crane design) and AS 2550 (safe use). Work health and safety obligations are also governed by Safe Work Australia’s national model WHS laws. You will also want to find specific licensing requirements for your state or territory.

Crane Maintenance and Inspections

We always stress the importance of regular maintenance to get the most out of your investment. A well-maintained crane is not only safer, but it also performs better and lasts longer.

Like any heavy machinery, cranes require scheduled servicing in line with manufacturer guidelines and Australian Standards. This includes regular inspections of hydraulic systems, structural components, safety devices, and control systems.

Some common issues to watch for include:

- Leaking hydraulic hoses or cylinders

- Excessive wear on pivot points or pins

- Corrosion, cracks, or structural fatigue

- Faulty limit switches or control malfunctions

Many first-time buyers underestimate the value of a solid service plan or support partner. Partnering with a crane supplier who offers expert servicing, genuine parts, and responsive after-sales support can reduce downtime, prevent costly repairs, and ensure ongoing compliance.

The trick is to think of maintenance not as a cost, but as future proofing for your crane, your crew, and your business.

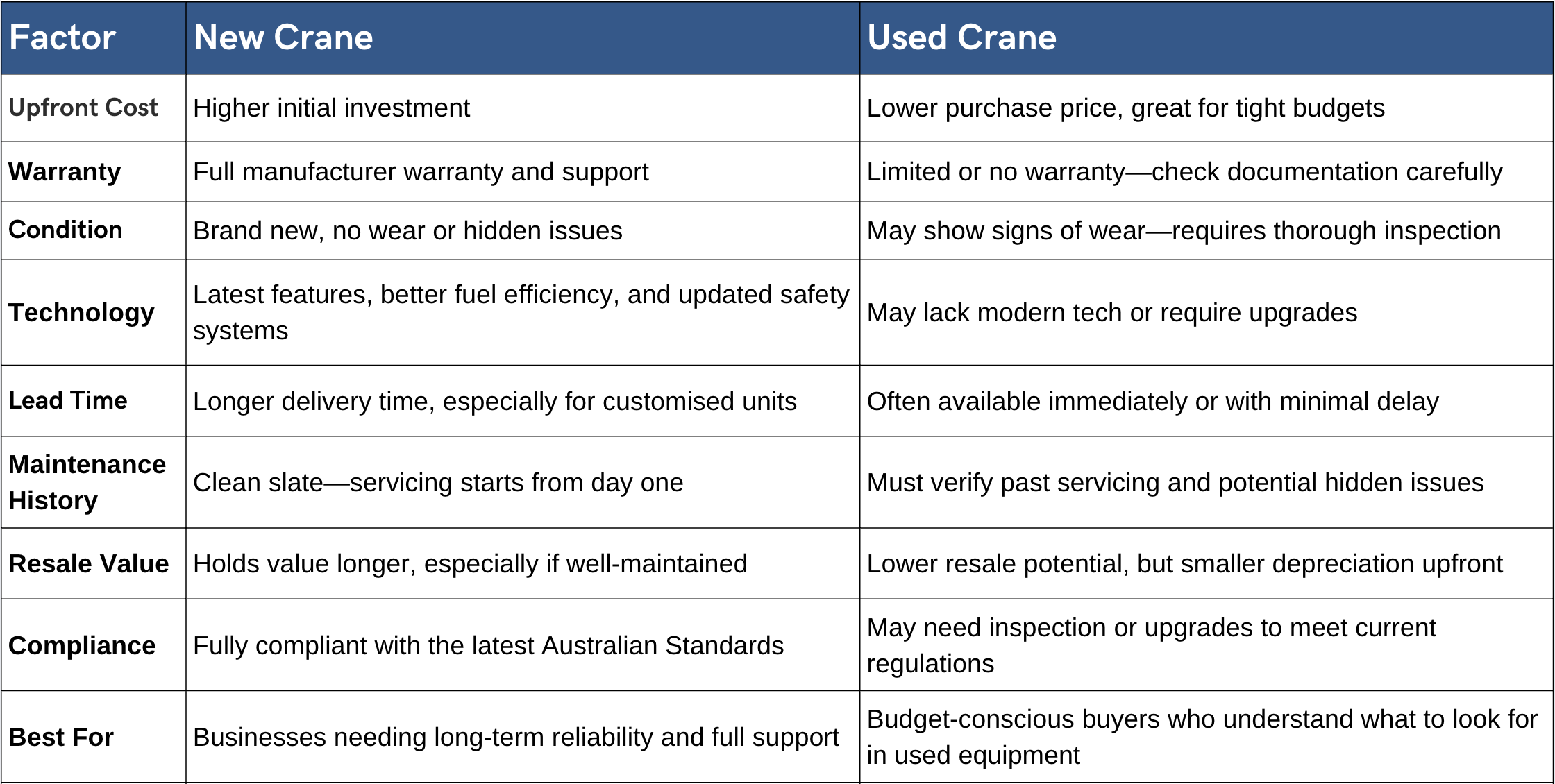

New vs Used Crane – Which Should You Choose?

Here’s a comparison chart to help you decide whether to speak with crane rental companies or a crane provider.

Final Thoughts: Making an Informed Investment

With the right preparation, crane ownership can be one of the smartest investments your business makes. From understanding the true costs and choosing the right crane type, to staying on top of licensing and maintenance, a little due diligence saves you time, money, and stress down the track.

Still unsure? Browse our range of cranes and speak with one of our crane specialists today. We’re here to help you find the right solution for your needs, whether you’re buying new, used, or just weighing your options.