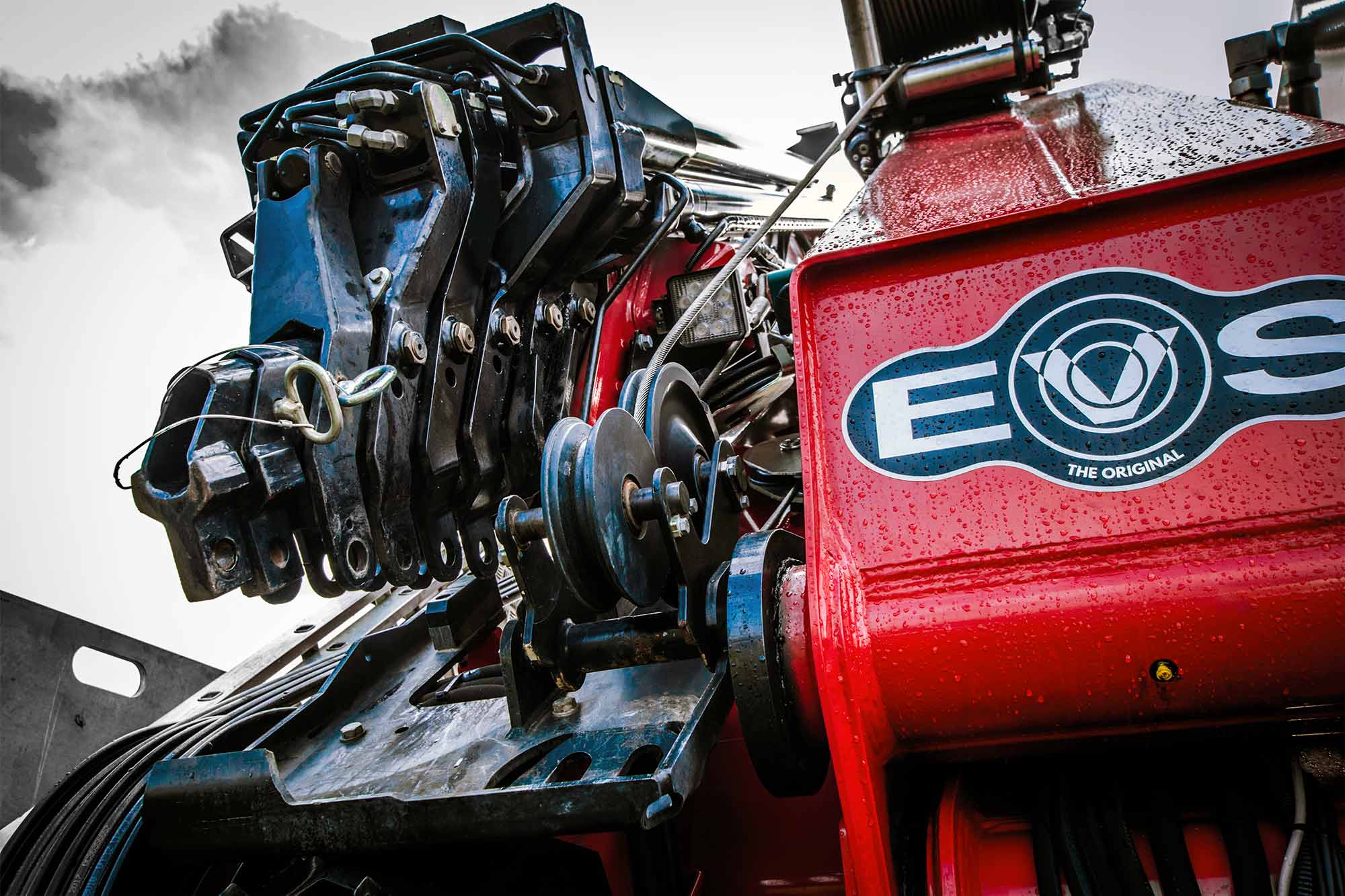

When operating heavy-duty cranes in challenging environments, stability is paramount. That’s where EVS comes in—an innovative system that silently works to protect both the crane operator and everyone in the surrounding area.

EVS stands for Electronic Vehicle Stability and is based on sensors that constantly analyse the situation of the vehicle. If the system recognises a heel that’s bigger than what’s considered safe, the speed will be reduced or even stopped straight away.

Let’s explore what makes Electronic Vehicle Stability such a crucial safety feature for loading cranes and break down how it works, the technology behind it and why it is essential for preventing dangerous situations such as a truck rollover.

How Does Electronic Vehicle Stability Work?

Whether you’re researching safety features, are interested in vehicle stability control, or are looking to prevent operational incidents, understanding EVS is the key to efficient on-site operations.

The sophisticated technology monitors and manages crane stability, allowing operators to work safely within the crane’s capabilities. Essentially, EVS ensures that HMF crane trucks remain balanced during heavy lifting and actively monitors vehicle stability for RC and RCS cranes.

Sensors collect data about the crane’s load, boom angle and outrigger positions, and crane base angle. Computer systems then process this real-time data to detect any potential imbalances or risks in the surrounding environment.

This continuous monitoring focuses on multiple critical factors to ensure safe operation:

- The load on both the vehicle and the crane

- Operating speed

- Heel (tilt) of the vehicle

These observations allow a warning to be given before a situation becomes critical. The operator can be confident in trusting the system to limit any inappropriate or potentially dangerous movements automatically. Most of the time, you won’t actually notice it’s active.

The Role of EVS in Modern Crane Operations

Modern loading cranes benefit significantly from the integration of EVS. One of the biggest advantages of EVS is being able to use the payload on the truck for extra stability, meaning in some scenarios the operator may get full lifting capacity even with the stabilisers short-legged, which can make it convenient for operations in tight spaces.

The EVS system works alongside other crucial safety features on HMF cranes to provide comprehensive protection:

- Load Moment Indicators: This system constantly monitors the crane’s load and ensures operations don’t exceed the crane’s safe lifting capacity. These systems work in tandem to provide complete load management and stability control.

- Outrigger Sensors: These ensure the crane support system is properly deployed before lifting begins and factor in the outrigger position into the overall stability assessment.

This integration of multiple safety systems allows EVS to make comprehensive stability assessments based on all critical factors affecting crane operation.

Benefits of Electronic Vehicle Stability in Loading Cranes

EVS has proven its ability in the construction field with over 20 years of tried, tested and approved use.

- Enhanced Safety: One of the most significant advantages of EVS is its ability to prevent tipping and other load-related accidents. Constantly monitoring and adjusting the crane’s stability helps reduce operator errors and overall risk.

- Improved Operational Efficiency: Electronic Vehicle Stability with automatic stability adjustment allows drivers to manoeuvre with greater confidence, leading to faster and more precise operations. Reduced risk of accidents means less downtime and higher productivity.

- Easier to Focus on Work: The user-friendly nature of EVS means whoever is operating the crane can concentrate on the task at hand without distraction. Rather than requiring constant manual monitoring of stability conditions, the system automatically responds to operator actions, maintaining vehicle stability.

- Flexibility and Reliability: EVS provides a robust and adaptable enhancement that ensures cranes can handle varied operational challenges without the usual safety problems. The system has been refined over the years, proving a reliable method for accident prevention in a range of different environments and applications.

- Tried, Tested, and Approved: EVS has been in successful operation on vehicles all over the world for more than 20 years. Not only that, but it’s been approved according to the EN 280 for working with personnel baskets, which requires compliance with particularly strict demands for both safety and reliability.

Shop Loading Cranes with Peace of Mind

It’s important to note that EVS is not included on all HMF cranes but is available as an upgrade option. Investing in loading cranes that are equipped with EVS, or retrofitting older models with this technology, is a smart decision that will reduce the risk of accidents, enhance operational efficiency, and assist in regulatory compliance.

Not only does it improve safety, but it also boosts productivity by reducing downtime and allowing operators to perform more confidently. For a safe and more efficient crane operation, consider adding EVS to your fleet. Contact the team at HMF Australia for more tips and advice.